Which Gauge Is Thicker 14 Or 16? The Ultimate Guide For Beginners

So here's the deal, if you're asking yourself, "which gauge is thicker 14 or 16?" you're not alone. A lot of people get tripped up by this question, and honestly, it's not as straightforward as it seems. Whether you're working with wires, jewelry, or sheet metal, understanding gauge thickness is crucial. Let me break it down for you in a way that's easy to digest, but still gives you all the juicy details you need.

You see, the gauge system works a little backward compared to what most folks expect. Smaller numbers actually mean thicker materials, while larger numbers mean thinner ones. So, when we're comparing 14-gauge and 16-gauge, the answer is simple—14-gauge is thicker. But there's so much more to the story than just this basic fact. Stick around, and I'll walk you through everything you need to know.

This guide isn't just about answering the question; it's about helping you understand why gauge matters, how it affects your projects, and how to choose the right gauge for whatever you're working on. Let's dive in!

Read also:Eva Elfie And Jason Luv Exploring The Rise Of A Musical Power Couple

Table of Contents

- Understanding Gauge Basics

- 14-Gauge vs. 16-Gauge: What's the Difference?

- Common Applications for Different Gauges

- Gauge Thickness Chart: Your Go-To Reference

- How to Choose the Right Gauge for Your Project

- Gauge in Jewelry Making

- Gauge for Electrical Wires

- Gauge in Sheet Metal Work

- Tips for Working with Different Gauges

- Wrapping It All Up

Understanding Gauge Basics

Gauge is a term that gets thrown around a lot, especially in industries like jewelry making, electrical work, and metal fabrication. But what exactly does it mean? Simply put, gauge refers to the thickness of a material, whether it's wire, sheet metal, or even body jewelry. The system works on a scale where smaller numbers indicate thicker materials, while larger numbers mean thinner ones.

For instance, if you're working with sheet metal, a 14-gauge piece will be noticeably thicker than a 16-gauge piece. This difference might seem small, but it can have a big impact on the strength, flexibility, and durability of whatever you're creating. Understanding these basics is key to picking the right material for your project.

Why Gauge Matters

Here's the thing: choosing the wrong gauge can ruin your project before it even starts. If you go too thin, your material might not be strong enough to hold up under stress. On the other hand, if you go too thick, it might be harder to work with or require more powerful tools to shape. That's why knowing the difference between gauges is so important.

14-Gauge vs. 16-Gauge: What's the Difference?

Alright, let's get back to the main question—which gauge is thicker 14 or 16? As we already established, 14-gauge is thicker than 16-gauge. But how much thicker, exactly? Well, that depends on the material you're working with. For example:

- 14-gauge wire has a diameter of about 1.628 mm.

- 16-gauge wire has a diameter of about 1.291 mm.

While this might not seem like a huge difference, it can make a big impact when you're working on intricate projects. The extra thickness of 14-gauge can provide more strength and durability, while 16-gauge offers a bit more flexibility and ease of use.

When to Use 14-Gauge vs. 16-Gauge

The choice between 14-gauge and 16-gauge often comes down to the specific needs of your project. Here are a few scenarios where one might be better than the other:

Read also:Lilith Berry Leaked The Truth Behind The Controversy And How To Protect Your Privacy

- For heavy-duty applications, like structural supports or large jewelry pieces, 14-gauge is usually the way to go.

- For more delicate work, like earrings or small wire wraps, 16-gauge might be a better fit.

Common Applications for Different Gauges

Now that we've covered the basics, let's talk about where you're most likely to encounter different gauges in real-world situations. Depending on the industry you're working in, the gauge you choose can vary widely.

Jewelry Making

In jewelry making, gauge is everything. The thickness of the wire or metal you use can affect the look, feel, and durability of your pieces. For example:

- 14-gauge wire is great for making sturdy bracelets or necklaces.

- 16-gauge wire works well for smaller pieces like earrings or delicate pendants.

Electrical Wires

When it comes to electrical work, choosing the right gauge is crucial for safety and efficiency. Here's a quick breakdown:

- 14-gauge wires are commonly used for standard household wiring, like lighting and outlets.

- 16-gauge wires are often used for lower-power applications, like lamps or small appliances.

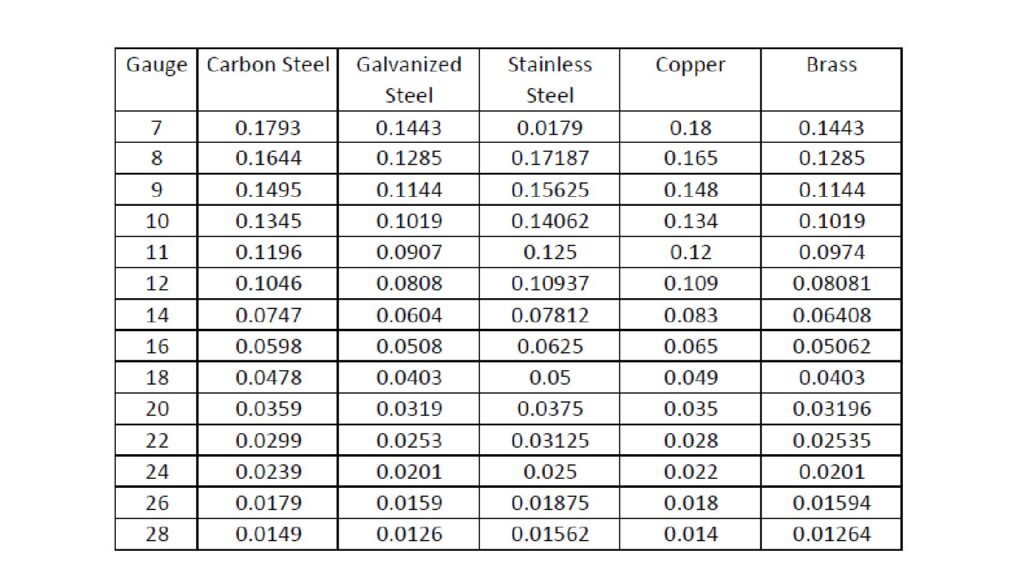

Gauge Thickness Chart: Your Go-To Reference

To make things easier, here's a quick reference chart you can use to compare different gauges:

| Gauge | Wire Diameter (mm) | Sheet Metal Thickness (mm) |

|---|---|---|

| 14 | 1.628 | 2.0 |

| 16 | 1.291 | 1.6 |

Keep this chart handy whenever you're working with different materials. It'll help you quickly determine which gauge is best for your project.

How to Choose the Right Gauge for Your Project

Picking the right gauge isn't always easy, especially if you're new to working with metals or wires. Here are a few tips to help you make the right decision:

- Consider the weight and stress your material will need to handle.

- Think about the tools you have available and whether they can handle thicker or thinner materials.

- Take into account the aesthetic you're going for—sometimes thinner materials can create a more delicate look.

Questions to Ask Yourself

Before you settle on a gauge, ask yourself these questions:

- What's the purpose of my project?

- How much weight or stress will the material need to withstand?

- Do I have the right tools to work with this gauge?

Gauge in Jewelry Making

Jewelry makers know that gauge is one of the most important factors in creating beautiful, functional pieces. Whether you're making earrings, necklaces, or bracelets, choosing the right gauge can make all the difference.

Popular Gauges in Jewelry

Here are some of the most common gauges used in jewelry making:

- 14-gauge: Great for bracelets and heavier necklaces.

- 16-gauge: Perfect for earrings and delicate pendants.

- 18-gauge: Ideal for very fine details or small wire wraps.

Gauge for Electrical Wires

When it comes to electrical work, safety is the top priority. That's why choosing the right gauge for your wires is so important. Here's a quick rundown of some common gauges and their uses:

- 14-gauge: Standard household wiring for lighting and outlets.

- 16-gauge: Lower-power applications like lamps or small appliances.

- 12-gauge: Heavier-duty wiring for appliances like refrigerators or ovens.

Gauge in Sheet Metal Work

Sheet metal workers also rely heavily on gauge to determine the thickness of their materials. Whether you're building furniture, creating art, or fabricating parts for machinery, the gauge you choose can affect the strength and durability of your work.

Common Sheet Metal Gauges

Here are some of the most common sheet metal gauges and their uses:

- 14-gauge: Great for structural supports or heavy-duty applications.

- 16-gauge: Ideal for lighter projects or decorative pieces.

- 18-gauge: Perfect for very delicate work or intricate designs.

Tips for Working with Different Gauges

Working with different gauges can be a bit tricky, especially if you're new to it. Here are a few tips to help you get started:

- Always start with a gauge that's slightly thicker than you think you'll need. You can always file it down if necessary.

- Invest in good-quality tools that can handle the gauge you're working with.

- Don't be afraid to experiment with different gauges to see what works best for your project.

Wrapping It All Up

So, there you have it—the answer to the question, "which gauge is thicker 14 or 16?" is simple: 14-gauge is thicker. But understanding gauge goes way beyond just knowing which number is bigger. It's about knowing how to choose the right gauge for your specific needs and how to work with it effectively.

Remember, the key to success is doing your research and being prepared. Whether you're working with jewelry, electrical wires, or sheet metal, the right gauge can make all the difference. So take your time, choose wisely, and don't be afraid to ask for help if you need it.

Now it's your turn! Got any questions or tips of your own? Drop them in the comments below, and let's keep the conversation going. And if you found this guide helpful, don't forget to share it with your friends and followers. Let's spread the knowledge and help each other out!

Article Recommendations